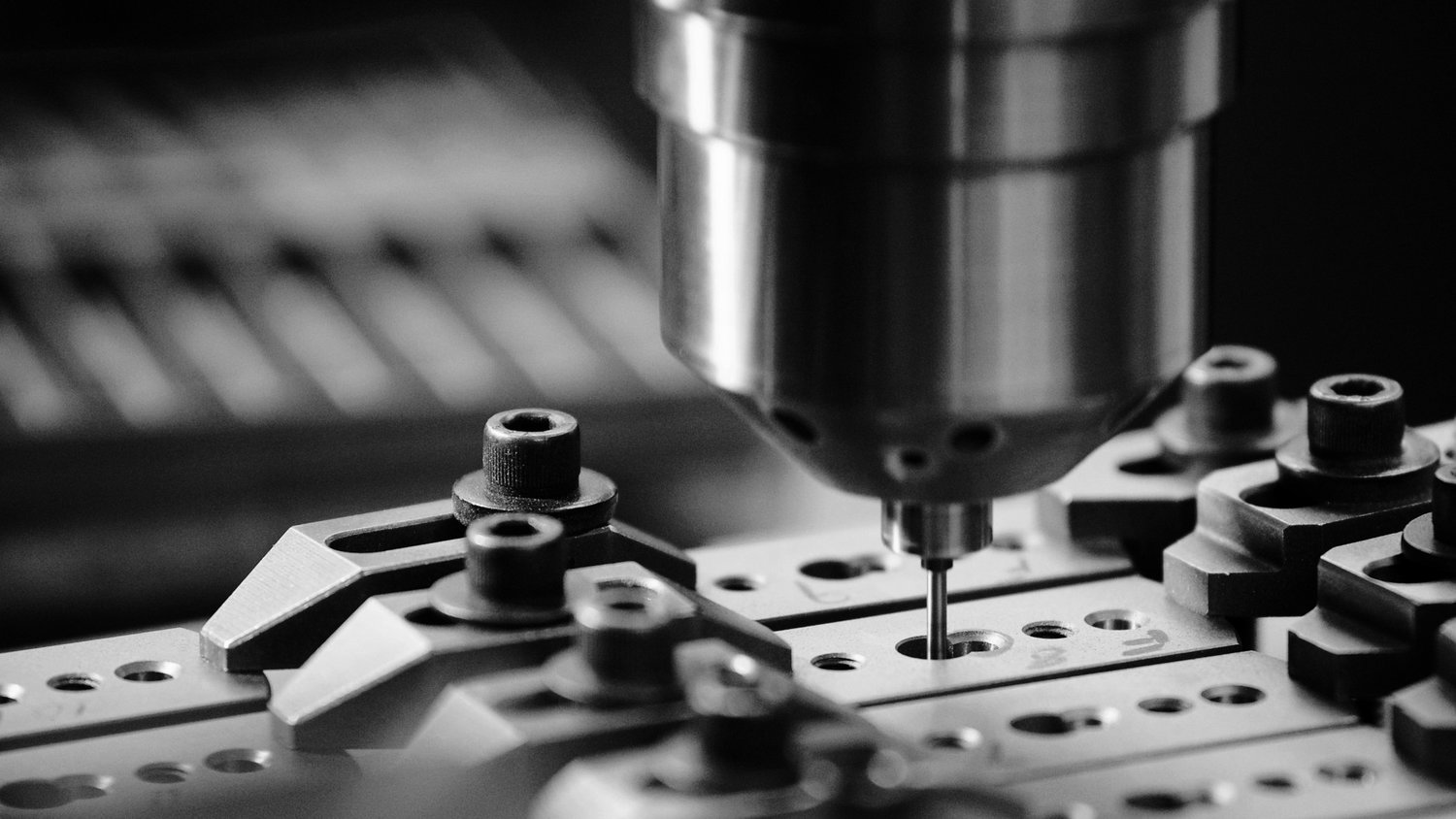

RAM utilizes leading edge technology to manufacture and produce high precision products within ±30 millionths of an inch tolerances (less than one micron).

By leveraging precision grinding, precision machining and advanced engineering software, we produce results which decrease scrap and ensure the highest quality.

RAM is known for precision manufacturing as well as rapid turn on prototypes. RAM's operation is driven with precision and efficiency.

Precision Grinding: Our consistent high quality precision grinding is accomplished with CNC jig grinders, NC surface, rotary, radius and centerless grinders for consistently high-quality results. RAM incorporates proprietary cam grinders for non-round geometry commonly used in food and beverage container industries.

Precision Machining: Our comprehensive machining capabilities, combined with skilled staff, uses advanced software to reduce variability and eliminate processes that drive the most streamlined machining solutions. RAM's hard finishing capabilities practically eliminate the need for polishing. We machine a wide variety of geometries with our Multi-axis systems, eliminating the need for separate set ups and ensuring more consistent accurate results of the final product.

Software/Finishing: Utilizing the most advanced engineering and manufacturing software systems available in today’s market, our strategy reduces variability and produces high quality products for high-end machining centers. RAM's manufacturing process uses the latest version of SolidWorks and CAD/CAM Software to increase machining speeds in complex geometries and 3D shapes.